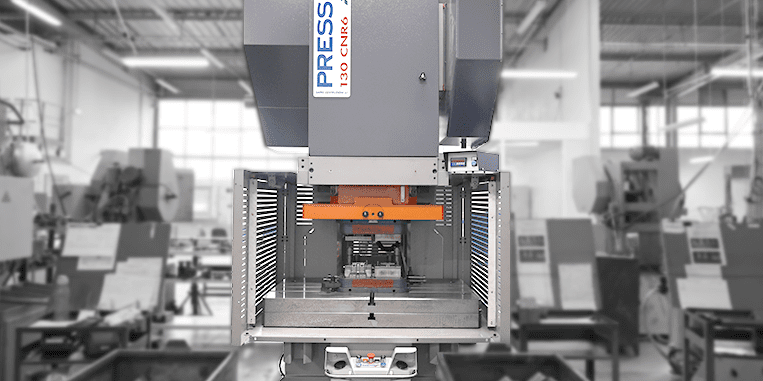

As a subcontractor for industrial punching, Groupe TMA ensures quality and precision in the cutting and shaping of your metal parts in repeat medium and large runs. Groupe TMA has a number of latest-generation automated stamping machines that enable it to offer a continuous service, 24 hours a day, 7 days a week.

We accompany you in punching steel, stainless steel and aluminium

In metalworking, mechanical punching makes it possible to cut and shape a sheet of metal placed between a stamp and a die. This is a precision process, ensuring tolerances of +/- 0.1 mm. Punching is a technique used for cutting, perforating, tapping, folding, deforming and coining; it is particularly suitable for producing metal parts in medium and long runs.

We produce punched parts for clients manufacturing electronic, electrical and thermal equipment, fittings, urban furniture, and items in other sectors of activity.

Our high-tech industrial punching machines

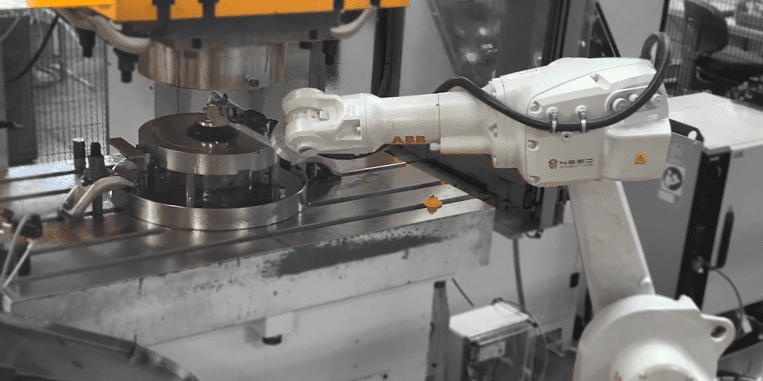

As an expert in the industrial sector, Groupe TMA is constantly investing in new technologies; it has a number of automated punching units with automated sheet metal input and metal parts output.

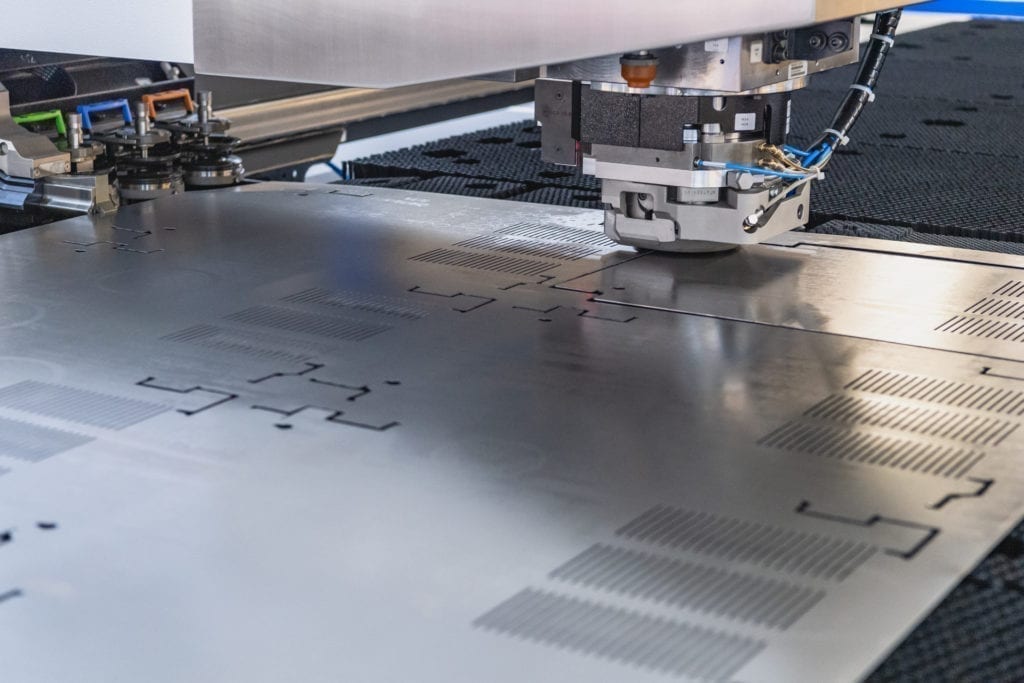

Groupe TMA operates a Trumpf punching machine – the fastest in the world – in order to be able to meet stringent market demands. Our punching unit carries out ribbing, dimpling, hollowing, scooping, and other types of deformation. Its brush table and integrated deburring tools provide an exceptional finish for your metal parts. Our machines process steel, stainless steel and aluminium sheets measuring up to 1500 x 3000 mm, with a maximum thickness of 6 mm.

For your punching projects, our specialists optimise manufacturing time by selecting the most appropriate tools. Groupe TMA maintains a large stock of machine tools so that it is able to produce made-to-measure metal parts of any kind.

Our stock of material for punching metal

We maintain a permanent stock of 600 tonnes of material, including sheets of steel, stainless steel and aluminium. We offer hot- and cold-rolled steel, S355, S235 and high-tensile steel, pickled and galvanised blackplate, and wear plates. Other grades are available to order.

Groupe TMA attests the traceability of the materials it uses and the compliance of all your metal parts by supplying, on request, a material certificate in accordance with NF EN 10204 – CCPU 3.1, the TÜV, US or any other technical inspection.