Groupe TMA specialises in cutting and processing metals as a subcontractor. As an expert in CNC and mechanical machining, Groupe TMA manufactures precision metal parts in runs of all sizes for all its industrial clients.

Fine machining of metal parts

This manufacturing process shapes the metal to a high level of precision by removing material. The operation is carried out by a machine tool, giving the blank the shape and dimensions set out in your specifications.

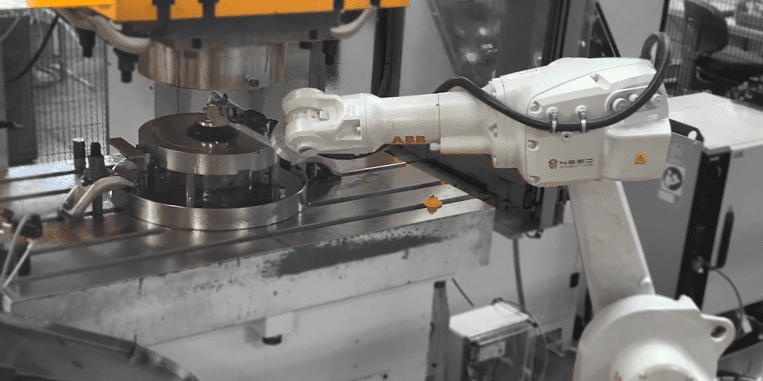

Groupe TMA’s specialists will take a close look at your project and optimise the manufacturing process. Our technicians ensure project continuity by applying CAD/CAM programming to your parts that are to be machined on our digitally controlled machinery. Our teams are experienced in machine milling, turning, reaming, chamfering, tapping, spot facing, threading and surfacing on metal. On request, we use a digital measuring arm to check the parts.

Groupe TMA puts all its professional experience and knowledge at your disposal so that the precision parts you receive comply with your specifications, however complex they may be.

Tolerance standards for machining

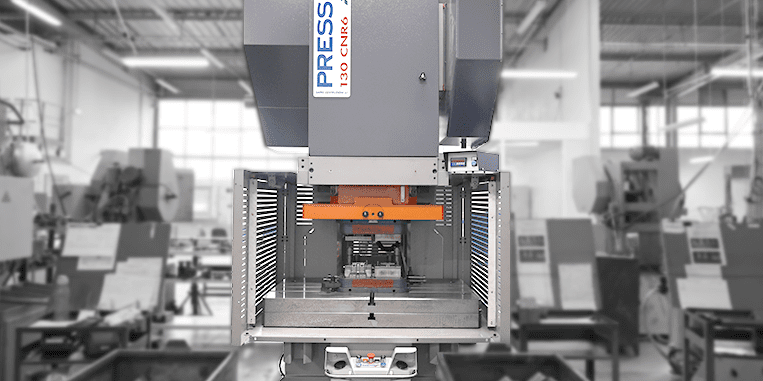

Digitally controlled machining and turning units

Groupe TMA has 5- and 3-axis machining equipment as well as state-of-the-art turning units. The work tables on our machining and turning units can cope with sizes up to 3000 x 800 x 700 mm and weights of up to 4000 kg. The tilting system incorporated in our machines allows the rapid changing of parts for machining runs. Our latest-generation equipment and large stock of embedded tools ensure efficient production.

Machining steel, stainless steel and aluminium

Our expertise in milling and turning enables us to machine steel, stainless steel, aluminium and any other type of metal to order. This high-precision technology has the advantage of producing parts with excellent surface finishes.