Groupe TMA is a specialist in stamp cutting, and carries out all kinds of metal deformation and precision cutting. From tool design up to the technical stamping of your metal parts, Groupe TMA is with you all the way, putting all its skill and experience at your disposal.

Skill in stamping metal

Stamping is a technique used to shape metal by deforming it without applying heat. Groupe TMA has specialised in the design of tools and the stamping of stainless steel, steel and aluminium since it incorporated a number of specialist units in 2006. Every year, the company produces tens of thousands of parts for the automobile industry, equipment manufacturers, the energy industry, the building sector, and many other areas of activity.

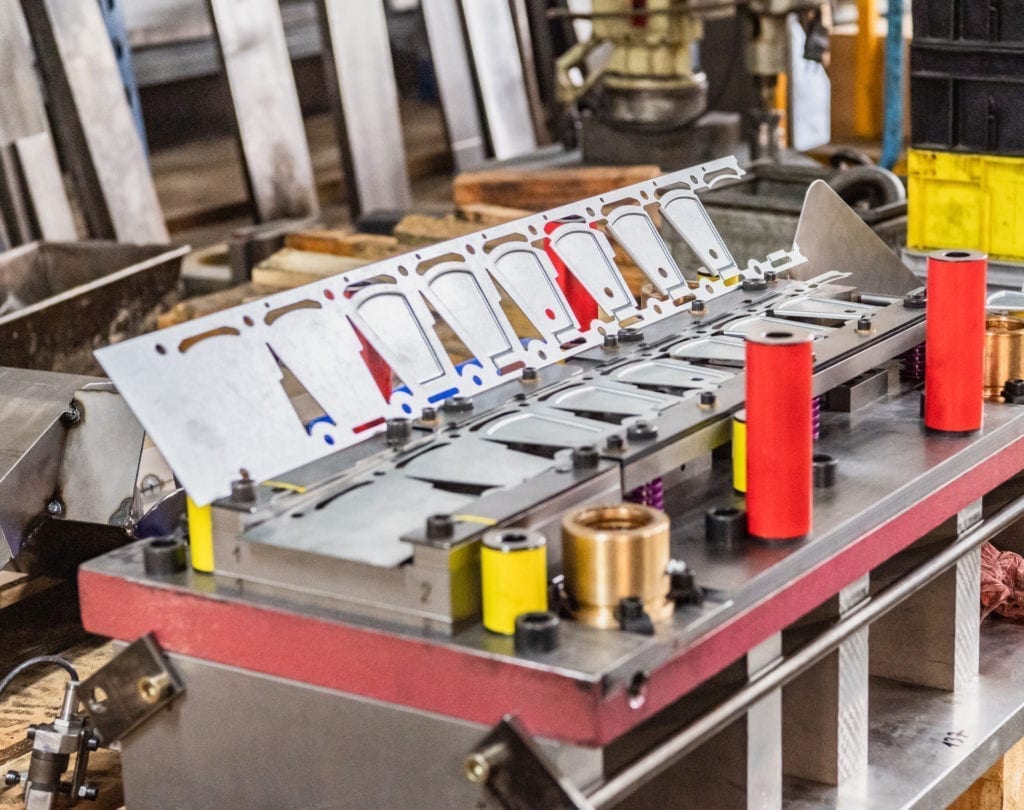

Made-to-measure stamping tools

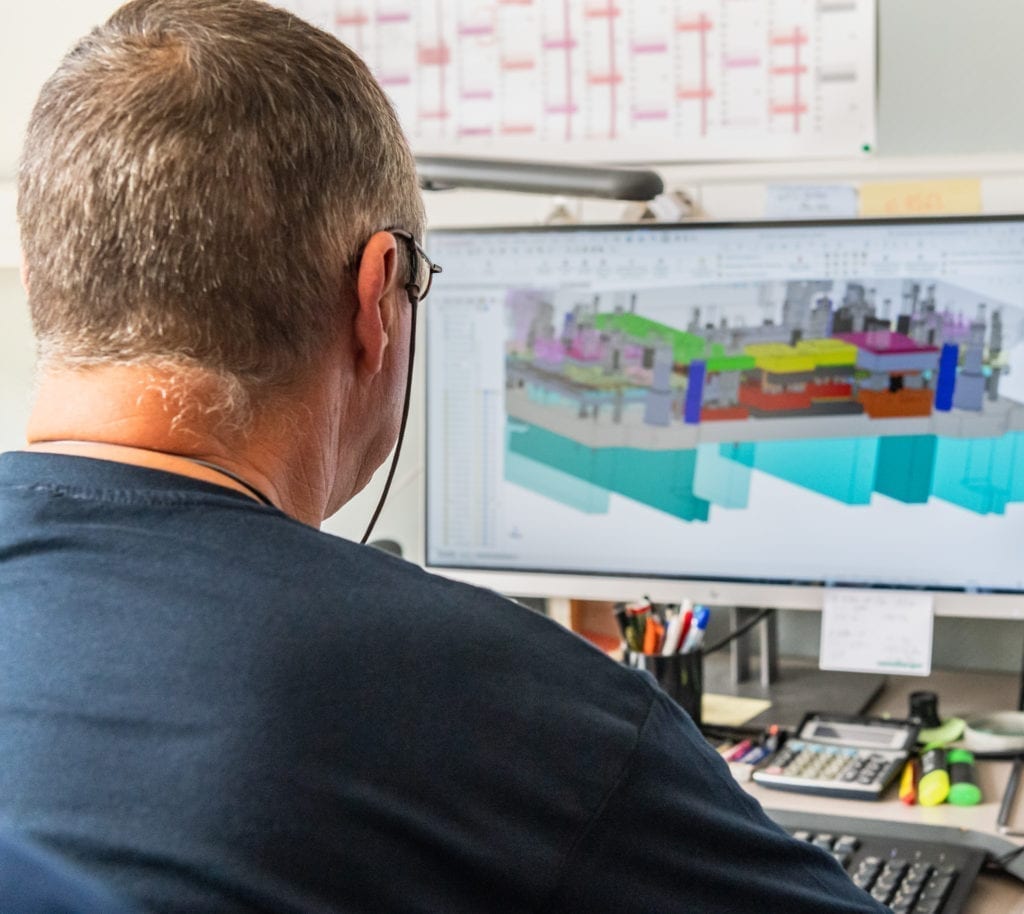

Right from the start of a project, our design office works in close collaboration with the client to co-develop the product in order to ensure that production costs are optimised.

Because the tools used are a vital part of the stamping process, Groupe TMA offers a global service, from their creation through to their maintenance.

The design office models the stamping tools in 3D for a virtual simulation before part manufacturing begins. To ensure quality and reliability, checks are carried out by sampling during the various stages in the production cycle.

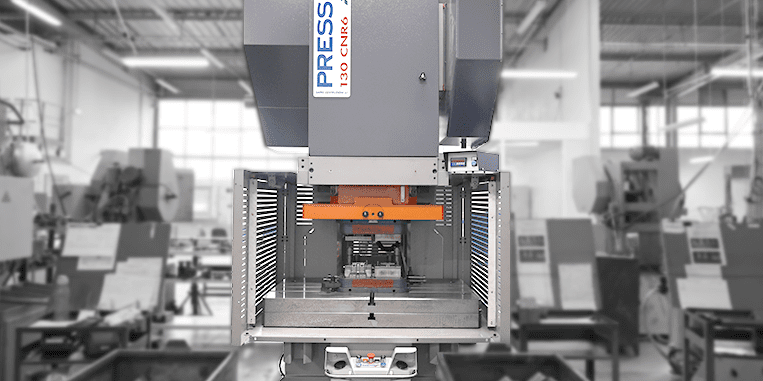

Our pool of stamping presses

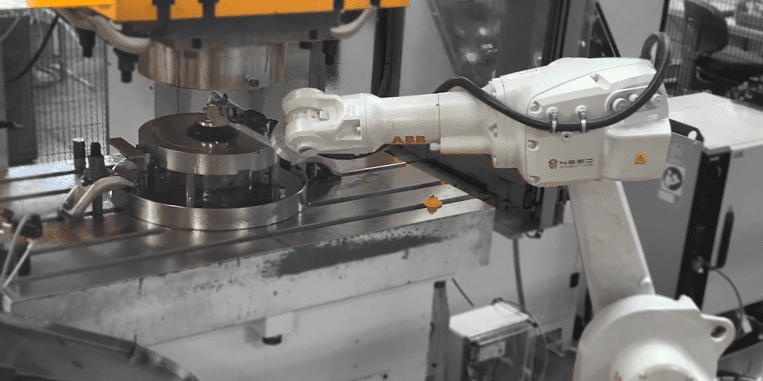

Our stamping machines, with a maximum power of 500 tonnes, are fitted with automated lines and unrolling lines, capable of shaping, cutting, punching and folding sheet metal up to 4 mm thick.

Groupe TMA puts its mechanical stamping presses at your disposal and accompanies you all the way through your project for repeat runs of parts, right up to assembly of the finished product.

Services in addition to the stamping of aluminium, steel and stainless steel

In addition to stamping, Groupe TMA offers riveting, crimping, welding, vibratory finishing, tapping, surface treatment and the assembly of your metal parts.