For the past 35 years, Groupe TMA has been providing oxyacetylene cutting services in Alsace for local and international clients. Whether metal is being cut for single parts or large runs, our expert oxyacetylene cutters put all their experience and skill at the client’s disposal.

Oxyacetylene cutting on steel

Oxyacetylene cutting is a thermal cutting process suited to cutting through thick metal. It calls for a high level of technical skill, and offers quality cutting for steel. Optimised imbrication combined with the simultaneous use of several torches ensures competitive prices.

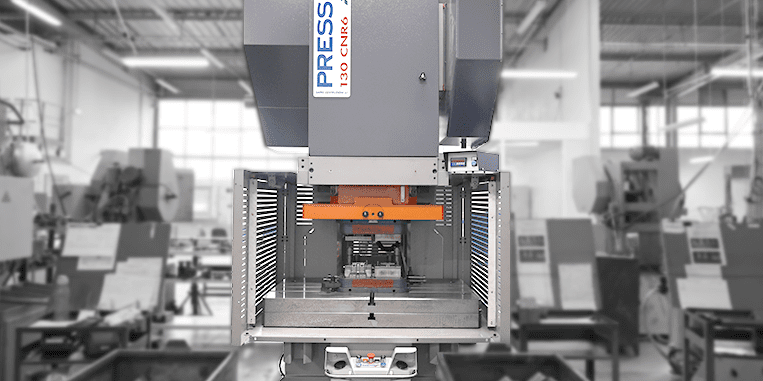

Our pool of oxyacetylene cutting machines

Our oxyacetylene cutting machines can cut through sheet steel between 15 and 300 mm thick on tables measuring 6 m x 20 m. Our machines are suited to industrial cutting: they are fitted with eight to twelve torches, ensuring production capacity ranging from a single part to a large run. This technology offers an effective response to the demands of the agricultural sector, the building industry, public works, equipment manufacturers, and other sectors.

Our stock of steel plates in standard and made-to-measure formats

Groupe TMA maintains a permanent stock of more than 400 tonnes of S235, S355 and high-tensile steel. We work on plates of standard sizes (2000 x 6000 and 2000 x 12000) or plates rolled to your own specifications; we also work on material supplied by the client.

To ensure the total traceability of the material and the compliance of your parts, we are able to supply, on request, a material certificate in accordance with NF EN 10204 – CCPU 3.1, the TÜV, US or any other technical inspection.

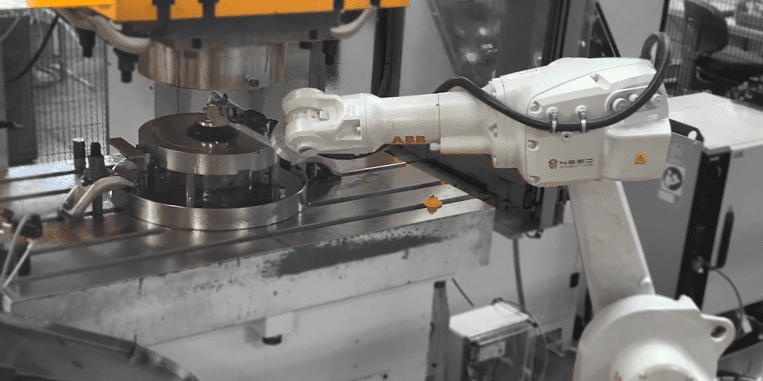

Our additional services and finishing operations

The finishing operations we offer include deburring, milling, and shot-blasting in a tunnel or drum. We also carry out other services on all your metal parts, including chamfering, straightening, marking, machining, folding and welding.